Clean & Modern Layout, Maple is packaged with awesome features, unlimited customizability, built-in mega menu, full WooCommerce design integration, and a super clean design, for minimal lovers.

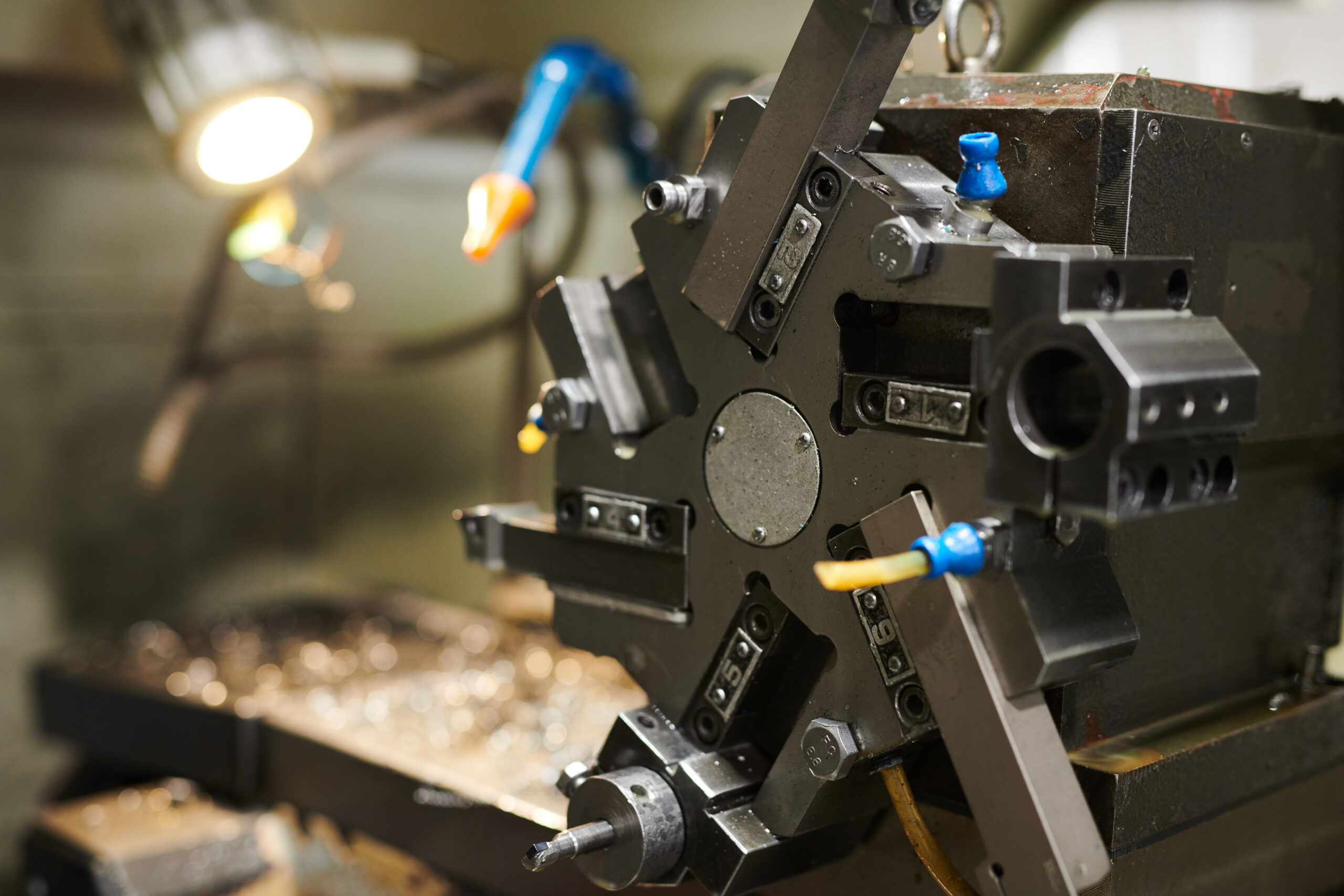

EXCEPTIONAL QUALITY & SERVICE

Our philosophy is to ingrain quality into every process, beginning with the quotation phase through the delivery of a completed order. As a turnkey manufacturer, our customers demand that we have uncompromised quality systems and procedures in place to ensure that the correct raw material is used for their product, that appropriately approved and qualified sub-vendors are utilized for all types of testing, coating, painting, welding, overlay, and any number of other processes which are involved in manufacturing a turnkey component.